Passing on industrial techniques with Xbox® accessories

When people first start riding a bike, they usually end up losing their balance and falling off – often. Riding a bike is a complex task that requires people to have the ability to keep their balance and use the pedals to propel themselves forward at the same time. However, when these skills are practiced separately, acquisition of the necessary skills becomes faster.

Many companies are putting in the effort to make it easy for people to master skills by extracting the individual components of those skills. Professor Toshiyuki Matsumoto of Aoyama Gakuin University has developed a system that utilizes Virtual Reality (VR) and Microsoft Kinect®. Kinect® is a gaming accessory for Xbox® 360 and Xbox® One gaming systems that recognizes gestures and sounds. But how does he use it?

Well, Professor Matsumoto developed the operation training system in collaboration with Oei Inc., a company in Kanagawa Prefecture known for high quality metal plate machining and coating. One of its key products is a range hood, an item that is exposed to steam and oil during cooking. A special coating technique is used to coat the range hoods, prevent erosion, and ensure they last for a long time. At Oei, new employees used to be taught how to apply the coatings by skilled trainers, but their eventual mastery of the technique often depended on the individual trainers.

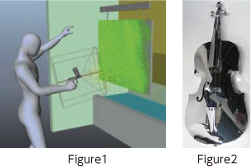

Professor Matsumoto’s system uses Kinect® to allow trainees to interact and learn from a VR reproduction of the process (as shown in Figure 1.) Comparisons can be made between the motions made by new employees and thos made by experienced employees, and the system can show where differences arise – and the extent of the difference – through the individual skill components. This system has made it possible for Oei to help employees master these skills in a way that is more consistent and quicker to complete. Aoyama Gakuin University has launched its Next-Generation Well-Being Project, which makes use of information technologies to enrich people’s lives. The system in use at Oei was developed as a part of this project.

Although this Kinect®-based system can train new employees to the intermediate level, it is not yet possible to train them to more advanced levels. Some Oei employees decided to work on improving their skills by designing and manufacturing a violin(as shown in Figure 2) made of metal for a contest. By challenging themselves in this way, they were able to make improvements to how they design metal molds, machine curved surfaces, polish metal, and weld. It is untiring efforts like these that help keep Japanese industry techniques alive and well.

松本俊之教授(青山学院大学理工学部経営システム工学科)

専門は生産工学、改善技術、生産管理, 生産情報システム, 環境教育。主に工場の生産性向上を工学的に研究。著書は『現場改善志向の生産情報システム』など。

このRESEARCHに関連するリンク